On February 1, 2013, Hiroshima University established two new programs: the “Distinguished Professors” (DP) program and the “Distinguished Researchers” (DR) program. Individuals who are part of these programs are recognized as senior and junior faculty members respectively, who are engaged in extraordinarily distinguished research activities.

In the natural environment, salt mixes with water in the ocean and carbon dioxide mixes with methane in natural gas deposits. The same mixing of molecules is common when chemists create useful compounds, as at the end of the reaction when leftover hydrogen mixes with ammonia, a chemical used in fertilizers and household cleaners. Usually only one molecule is valuable, but separating the desired molecule from the unwanted ones at the tiny, molecular-sized scale is a complicated task. One approach is to build a filter that only lets the desirable molecule pass through. Professor Toshinori Tsuru is a leader in the field of membrane science, dedicated to all aspects of the process of designing, building, and analyzing new styles and materials for membranes to separate molecules.

Distinguished Professor Toshinori Tsuru is currently the leader of the Separation Engineering Laboratory in the Graduate School of Engineering at Hiroshima University.

Layer One: Porous Supports

Membrane research has a straightforward goal: How can one molecule be physically separated from others? However, to create a truly successful membrane, researchers must consider a litany of other issues: environmental, medical, or industrial applications of the membrane; the fundamental chemistry of the molecules to be separated; the chemical properties of the materials that the membrane is built from; and the economic issues of a membrane’s performance versus the cost of its materials and manufacture.

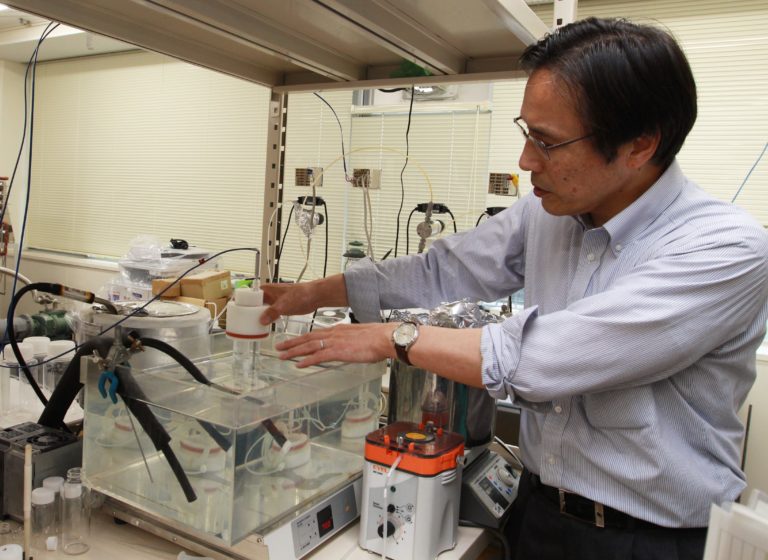

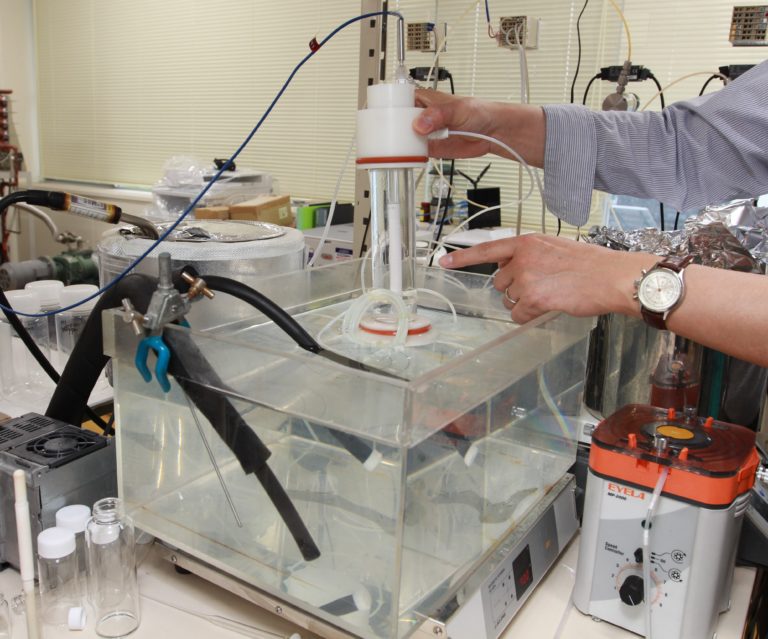

Tsuru describes how this membrane tube, built in his laboratory at Hiroshima University, will be suspended inside a larger pipe to improve the efficiency of water desalination.

One problem Tsuru has tried to solve with membranes is making drinkable water from seawater. Traditionally, the process used to remove salt from water is evaporation: boiling the water so that the salt stays in the pot while the freshwater steam is collected and cooled into drinkable water. The process is inefficient and not suitable for large-scale applications. However, a membrane to filter salt out of the water could provide a practical solution, if the membrane could resist bacteria and withstand being cleaned when necessary. Tsuru’s lab has designed improved desalination membranes that can function at industrial capacity and help solve global water shortages.

For water desalination and other applications, the membranes Tsuru’s lab group designs have three different layers. The bottom two layers are the porous support and the intermediate support, both of which help keep the membrane intact. The top layer is the first one that substances contact and has the pores that restrict unwanted molecules from entering. This separation layer is often less than 100 nanometers thick. Thin-film membranes with this basic structure can be built with different materials and pores sizes to separate different mixtures. Tsuru says that 20 years ago the only materials that membranes were made of were organic, because the technology to design membranes with inorganic materials had not yet been invented.

“Now we are mixing organic and inorganic components to make better membranes. It’s very fun,” Tsuru says, laughing.

Layer Two: Intermediate Structure

Professor Toshinori Tsuru completed his Bachelor and Master Degree at the University of Tokyo, where research was part of his studies and he worked in a small research lab, often as the only student. “Life as a researcher seemed very severe, and I did not have confidence that I could get good results,” he recalls.

That perception changed in the final semester of his undergraduate studies when he was finally captivated by a passion for discovery after some positive research results boosted his confidence. However, by that time Tsuru was already committed to a full-time job in industry, working for the Asahi Glass Corporation for about two and half years from 1985 to 1987. His interest in research remained throughout that time. When an opportunity to return to the University of Tokyo and earn a Doctorate in Engineering came, he took it.

“It was challenging to be back in academia, but I had decided to be a researcher. I made a good decision,” Tsuru says, laughing again. “But sometimes, I think I would say the same thing if I had stayed in industry. I am a chemical engineer, and I just enjoy this type work.”

Now, Tsuru leads the Separation Engineering Laboratory at Hiroshima University, a group that currently includes a total of 18 graduate and undergraduate students, three post-doctoral researchers, and two assistant professors. The inside of the Graduate School of Engineering building is a grid of white walls and blue doors, which provide a stark contrast to the rooms of equipment, which are packed to capacity with machines and students.

“I get good exercise doing experiments and meeting students and collaborators because my laboratory space is spread over four floors of the building!” Tsuru says, leading the way to an equipment room where his team creates cylinder-shaped membranes.

Tsuru demonstrates how the membrane tubes make drinkable water from seawater. Industrial desalination facilities are kept at specific temperatures, which is simulated in the laboratory by performing experiments in temperature-controlled water tanks.

Tsuru holds out one of the membranes, which looks almost like a narrow glass test tube with a thick, white insulating sleeve wrapped around most of the length. Rather than a disc-shaped membrane that is inserted into a tube, these membranes are built to be the tube. The white layer is the membrane and the glass only connects at the ends of the cylindrical membrane. This design should improve the efficiency of water desalination. Instead of pushing saltwater through many tubes with disc-shaped membranes, a larger pipe could be built around multiple membrane tubes. Then as saltwater is pushed through the larger pipe, fresh water that passes through the membranes into the tubes would be pumped out.

The innovative mindset that inspires these research accomplishments is reflected in the advice Tsuru gives to his students. “I always tell my students, think deep, wide, and quick. Then, take action!”

Layer Three: Separation

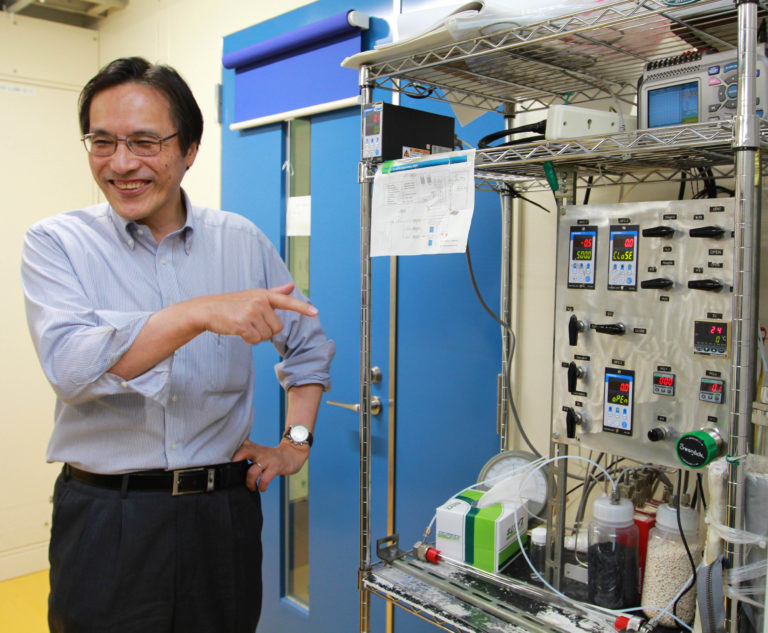

Tsuru’s own thinking has led not just to membranes, but also to new ways of evaluating the membranes he and other researchers build. The pores of membranes are measured in the same units used to describe wavelengths of light: angstroms. Pores in the separation layer of these nanomembranes can be between three to four angstroms in diameter, or 0.3 to 0.4 nanometers. The pores are too small to be seen even under Scanning Electron Microscopes, meaning it is a challenge for researchers to determine if a finished membrane has the pore size they intended. Tsuru designed a machine that can measure the size of a membranes’ pores using a technique he calls nanopermporometry, or NPP: nano, for the size; perm, for the materials permeating the membrane; and porometry, for the process of measuring pore size.

In narrow spaces like the pores of the membrane, the transition from a vapor to a liquid happens at a lower vapor pressure than in open spaces. Researchers use a standard mathematical formula to calculate the pressure at which a vapor will condense into a liquid in pores of different diameters. If drops of liquid block the pores, less air can travel through the membrane.

The NPP machine measures the ratio of air to liquid permeating the membrane as researchers change the pressure in the machine. The amount of air coming through the membrane at a particular pressure reveals how many pores are a particular diameter. If all the pores are identical, there will be a corresponding pressure where no air will come through the membrane because all the pores will be blocked with drops of liquid.

“Originally, I wanted to create such a machine so I could better understand what membranes I was actually building. Now the technique is useful for other membrane researchers, and it always is so rewarding to read a new research paper and see other groups using the technique I designed,” Tsuru says.

Tsuru explains the nanopermporometry technique he designed and the machine that uses this method to evaluate the pore size of membranes built in his laboratory.

The technique is now cited in research papers written by other scientists and the machine has been commercialized. Tsuru estimates that about 12 of the machines are now used by membrane researchers in four countries.

In addition to the ongoing projects to separate different liquids and gasses using multiple styles of membranes, Tsuru has plans for other new projects.

“I want to design a system that would combine a chemical reaction with a membrane to isolate the desired product immediately before it gets mixed in with byproducts and leftover reactants. Such a system would be useful for processes like industrial production of hydrogen, because the current techniques are expensive and energy inefficient. And I am excited about 2D materials, like single-molecule thick graphite sheets. With such a material, you could build a separation layer of a membrane where all the pores are identical. But first we must build the right materials before we can create such membranes,” he says.

Home

Home