On February 1, 2013, Hiroshima University established two new programs: the “Distinguished Professors” (DP) program and the “Distinguished Researchers” (DR) program. Individuals who are part of these programs are recognized as senior and junior faculty members respectively, who are engaged in extraordinarily distinguished research activities.

Interview of Distinguished Professor Toru Yamamoto

The world’s first technology for designing control systems using databases and AI, whose evolution is being accelerated by an open research forum between universities and multiple companies

Control engineering for energy conservation, profit growth, and the SDGs

My field of expertise is control engineering. Many of the things that move around us have a control mechanism. By making them run efficiently, we can save energy and labor, which in turn creates added value such as cost reduction and increased profits, and will help us achieve the SDGs goals. I am fascinated by this aspect of contributing to society, which gives me the motivation to continue my research.

What I am pursuing is a new kind of control system design, one that differs from conventional designs. Control system design is usually based on the idea that we want to move the controlled system in a certain way, so we need to determine the inputs in such a way that it makes this happen. In order to do this, the relationship between input and output must be described in the form of a model. However, as the operating environment changes, the way the system works (system characteristics) will naturally change. For example, when controlling the temperature of water, even if the same amount of energy is applied, the temperature will obviously rise differently in summer and winter. This means that we have to create many models for different operating environments, and we also have to figure out how to switch between them. This makes the controller design very complicated. As such, my research is based on the design of a “data-driven control system” that does not use models in the first place, but controls the system directly from its own data.

By the way, the adaptive learning control method is a method for controlling a system whose characteristics change depending on the operating environment. In this method, the control parameters are updated in response to changes in the system characteristics, so the control parameters are rewritten each time, and even if the desired control performance is obtained, the control parameters are not recorded. Even if favorable control performance was obtained under similar conditions in the past, the control parameters at that time do not remain, so the control parameters have to be calculated again as a new system. This is inefficient and the stability (safety) of the system cannot be maintained. To solve this problem, I developed a “database-driven control method” in which input/output data and control parameters are paired and stored in a database, and the database is trained by AI to automatically calculate the control parameters to obtain the desired control performance, thereby improving the control performance.

In addition to the input and output data, information on the environmental and operating conditions is also stored in the database, and if the database (control parameters) is allowed to learn, it is possible to calculate the control parameters based on the data of similar conditions used in the past, even under operating environments encountered for the first time. Efforts to design control systems directly from operating data have been actively made both in Japan and overseas, but the idea of storing past data in a database and controlling it through adaptive learning via this database is original to our laboratory and the first attempt of its kind in the world.

The first product with this control method was released to the market in 2017 in the form of a temperature controller produced by an electronics manufacturer with whom we had been collaborating. Depending on the situation in which it is used, the control of temperature requires quite precise tracking and must be adjusted based on the experience and intuition of a skilled operator. With this temperature controller, it is possible to instantly track the desired temperature without the need for operator adjustment. We are also conducting trials for implementing this control system in other applications, such as automobiles, construction machinery, and injection molding processes for plastic products. Recently, we have published a book on database-driven control algorithms and their application to real systems.

Prof. Yamamoto with his book "Data-Oriented PID Control" (Morikita Publishing Co., Ltd., 2020)

The reward of seeing my work put to practical use through joint research with companies

The most important thing for me in my research is to conduct research and development so that my ideas can be put to use in society. I spend a lot of time talking with companies and customizing the control technology that I devise so that it can be used by each company. I think my style of always looking at the field and working with companies with practical application in mind has become part of my identity.

In 2018, we were selected for the Cabinet Office’s Regional University and Regional Industry Empowerment Grant Project, and the Digital Monozukuri (Manufacturing) Education and Research Center was established within the university as a base for building a new model of industry-university collaboration and fostering highly specialized human resources. As part of this project, I launched the “Data-Driven Smart System Co-Creation Consortium” as a project leader, and am currently engaged in co-creation initiatives with 17 companies.

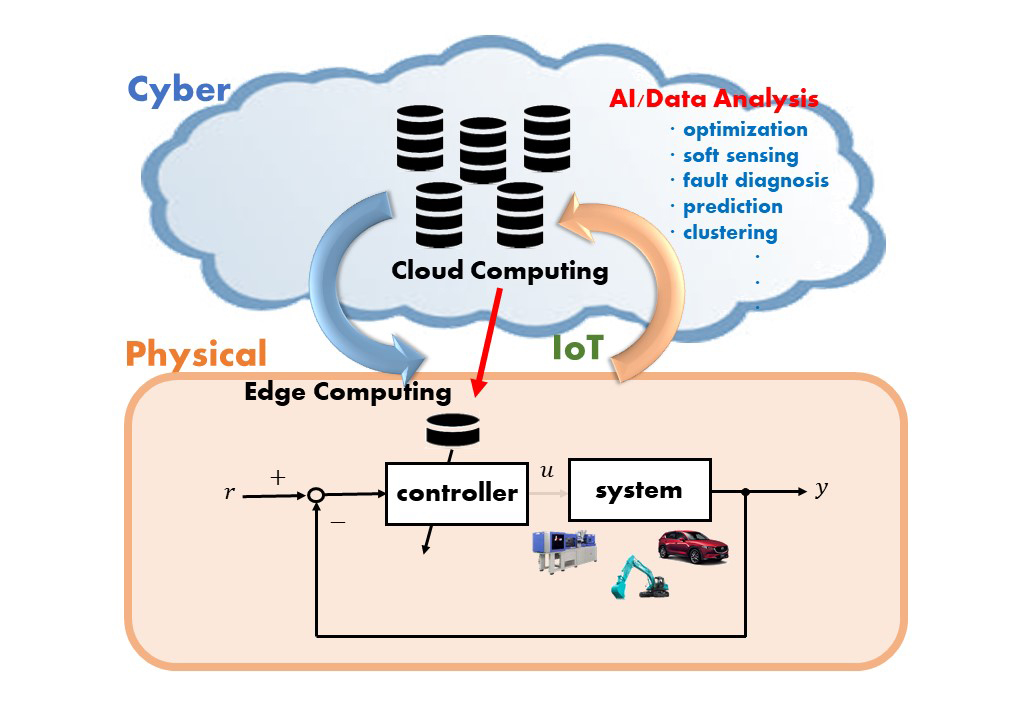

Co-Creation Consortium training session in progress

In my laboratory, about 20 engineers from companies have been temporarily assigned to work with about 40 students on research and development. Although we are working on different systems, we share the same technology, so I am grateful that everyone is able to work together under the concept of open innovation to develop and customize technologies to meet the needs of their own companies, which is a very progressive approach. When companies present us with new challenges, it gives us an opportunity to expand the scope of application and develop new control methods, which also has a positive impact on our students. We are also fostering synergy effects by expanding collaboration among universities, for example, by inviting professors from other universities in Japan and overseas to join our projects. The data accumulated in the database can be used not only for control, but also for predicting and diagnosing failures, and optimizing the entire system. At present, we are working on building a smart system that integrates all of the data so that it can be used effectively for these various purposes, and eventually we will be able to build a “database-driven cyber-physical system” with this as its core. This is a project that can only be accomplished by joining forces with multiple companies. By collaborating with companies, we are able to make new discoveries, and it makes me happy to see our technology spread and become useful to the world. This is what makes my work so rewarding.

Schematic diagram of a database-driven cyber-physical system

Home

Home