pr-research*office.hiroshima-u.ac.jp (Please change * into @)

100% natural, 100% gluten free - get ready for the battle of the grain.

By Richard J. O'Connor

Originally Published on March 22, 2017

Successful Rice Flour Bread

Hiroshima University researchers have resolved the science behind a new bread-baking recipe. The method for making gluten-free bread, developed by Japan’s National Agriculture and Food Research Organization, NARO - uses rice-flour to produce bread with a similar consistency and volume to traditional wheat-flour loaves.

While rice-flour breads are not new, up until now their consistencies have either lacked the familiar bubble structure and volume found in wheat-flour bread – or this bubble structure has been artificially induced through additives.

This new rice bread is 100% natural, and importantly has a similar consistency expected by consumers used to wheat breads. This gluten-free alternative should appeal to celiac sufferers who can’t consume gluten, and to people who wish to avoid gluten in their diets.

How it works

Wheat-flour bread’s familiar texture is down to gluten’s ability to form a flexible matrix. This matrix stabilizes the thin dough/bread walls that form between CO2 bubbles released by fermenting yeast. It also enables bread to “rise” in response to increasing CO2 levels during the baking process.

Rice flour does not contain gluten so how are these vital bread characteristics achieved in this new bread recipe?

The secret lies in the processing of the rice flour used. Not all rice flours produce a satisfactory batch, hence why this simple technique has remained undiscovered for so long! NARO found that rice flour produced by a specific type of wet milling was the key.

Using this wet-milled flour to make bread, they observed the microstructure of the fermenting batter (rice flour does not form dough), and the resulting loaf - both contained bubbles coated in uniform undamaged starch particles in a “stone wall” arrangement.

When Hiroshima University researchers investigated this ingredient, they found it possessed amazingly novel properties not seen in rice-flour before – and these were down to the undamaged starch particles that resulted from its specific milling technique.

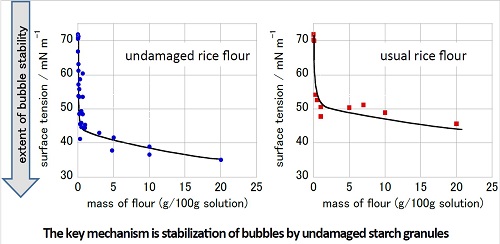

These stable “stone walls” apparently form due to the surface activity demonstrated by undamaged starch granules. It appears these granules are able to lower the surface tension of water and so reduce the tendency of the formed bubble walls to collapse! Other rice-flours tested, consisting of damaged starch, did not have the same water-tension lowering effect. They were thus devoid of these stable bubbles, and attempts to make bread with them fell flat.

Another factor hypothesized for undamaged starch bubble-stability in successful bread production is the uniform hydrophobicity of the similar sized granules - leading to their confinement to the interface between damp gaseous air pockets and the liquid batter.

This tightknit “stone wall” arrangement thus allows bubbles to grow and expand as CO2 levels increase within leading to successful voluminous bread.

Great Potential

Should producers see the benefits of moving to gluten-free rice flour for bread production it could conceivably shift the focus of global grain production from the prairies and steppes of the world to the paddy fields of Asia.

This would contribute to increased rice exports at a time when consumption of the staple has decreased with the adoption of western dietary habits – including ironically the eating of more bread!

From a food science point of view - this newly discovered example of a food swelling mechanism could lead to the development of new unconceived foods with unique and exciting properties.

Effect of undamaged starch in reducing water tension

Full bibliographic information:

Authors: Hiroyuki Yano, Akiko Fukui, Keiko Kajiwara, Isao Kobayashi, Koh-ichi Yoza, Akiyoshi Satake, Masumi Villeneuve

Title: Development of gluten-free rice bread: Pickering stabilization as a possible batter-swelling mechanism

Journal: LWT - Food Science and Technology, 2017; 79: 632

DOI: 10.1016/j.lwt.2016.11.086

Professor Hiroyuki Yano (NARO) and Professor Masumi Villeneuve (Hiroshima University)

- Profile of Associate Professor Masumi Villeneuve

- Find more Hiroshima University news on our Facebook page.

Norifumi Miyokawa

Research Planning Office, Hiroshima University

Home

Home