Key points of this research results

- Effects of pulsation frequency and pipe geometry on wall heat transfer in steady and pulsating flows in pipes were investigated.

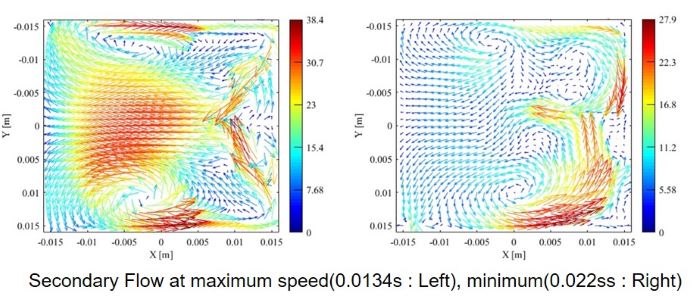

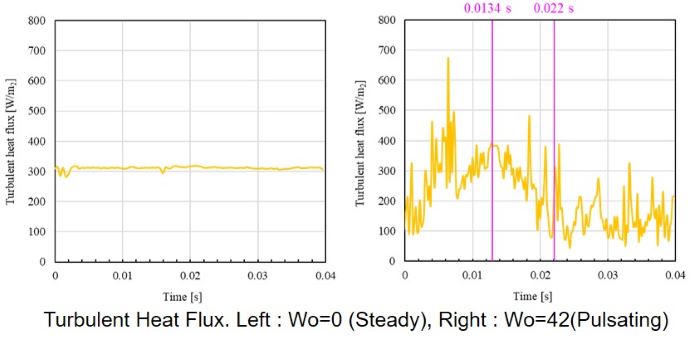

- It was found that turbulence in the flow field and the time variation of secondary flow and vortex structure at the bend, which occurs only in curved pipes, affect wall heat transfer, leading to heat transfer suppression and heat loss reduction in curved pipes.

- Flow field and vortex structures with short velocity pulsation periods and wall heat transfer mechanisms of the research results can contribute to design of heat loss reduction elements, for example from automotive exhaust manifolds with complex curved geometries.

Outline

Reduction of emissions of hazardous substances such as nitrogen oxides (NOx) in vehicle exhaust gases is an important and urgent topic for countermeasures against global environmental problems such as global warming. Exhaust gases from engine cylinders pass through a curved exhaust pipe and are purified by a three-way catalyst, but effective catalytic reaction activation requires a reduction of heat losses from exhaust pipes, and the correlation between the exhaust gas flow field and wall heat transfer characteristics in high-frequency pulsating turbulence can be used to find elements of heat loss reduction in real automotive engines. In collaboration with Mazda Motor Corporation, this laboratory investigated effects of pipe bends and flow fields on wall heat transfer characteristics in steady and pulsating flow in straight and double curved tubes, simulating the geometry and operating conditions of an automobile exhaust system, by varying the Womersley number (Wo: normalized pulsation frequency) for Wo = 33-80. The maximum Nusselt number (Nu: dimensionless number used for heat transfer characterisation) and heat transfer enhancement in straight tubes used in this study was found to occur at Wo = 42-49, while the opposite effect of minimum Nu number and heat transfer suppression was found in curved tubes. Experiments and numerical simulations have shown that in pulsating flow, turbulence generated at Wo during acceleration and maximum flow velocity remains during deceleration, and in curved pipes, heat transfer is also enhanced by secondary flow at the bend, but in pulsating flow, the dominant effect is that the intensity of the secondary flow weakens during deceleration and wall heat flux is smaller than in steady flow. The heat transfer suppression mechanism of high-frequency pulsating turbulent flow in curved pipes was clarified. The research results have been published in the scientific journal “International Communication of Heat and Mass Transfer”.

Published Paper

Y. Kato, K. Fujimoto, H. Yanagida, K. Nakamura, and Y. Ogata, Effect of the flow structure of pulsating turbulent flow in a duct with a double 90°bend on convective heat transfer at the wall,

International Communication of Heat and Mass Transfer (2025)

DOI : 10.1016/j.icheatmasstransfer.2025.108795

Home

Home