Inquiries on the study

Keita Marumoto

Assistant Professor

Graduate School of Advanced Science and Engineering, Hiroshima University

E-mail: maruk * hiroshima-u.ac.jp

(Note: Please replace * with @)

Inquiries on the story

Hiroshima University Public Relations Office

E-mail: koho * office.hiroshima-u.ac.jp

(Note: Please replace * with @)

The approach uses 3D printing to produce WC–Co cemented carbides—ultra-hard materials used in cutting and construction tools—while reducing the waste and cost of conventional manufacturing.

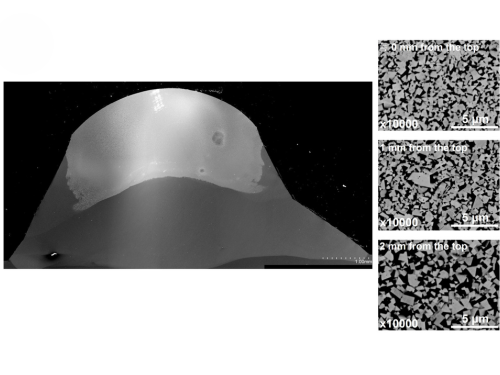

Scanning electron microscope image of a cemented carbide mold at the final stage of formation, produced using a laser-leading method with a Nickel-based alloy inserted in the middle layer.

(Courtesy of Keita Marumoto/Hiroshima University)

Tungsten carbide–cobalt (WC–Co) is prized for its hardness, but that same property makes it unusually difficult to shape. The current process is wasteful and expensive for the yield produced, and an economically sensible method for creating these materials is long overdue.

WC-Co cemented carbides are important in fields that require high wear resistance and hardness, such as cutting and construction tools. Currently, these carbides are made using powder metallurgy, utilizing high pressure and sintering machines to combine the WC and Co powders to yield a manufactured cemented carbide. Though this method does produce highly durable and hard final products, a lot of expensive material is used, and the yield is suboptimal. The research proposed in this study utilizes the novel technique of additive manufacturing (AM, also commonly known as 3D printing) and the hot-wire laser irradiation method to produce cemented carbides without sacrificing hardness and durability, while also reducing material waste and overall cost.

The study was published online in December 2025 in the International Journal of Refractory Metals and Hard Materials and will appear in the journal’s April 2026 print issue.

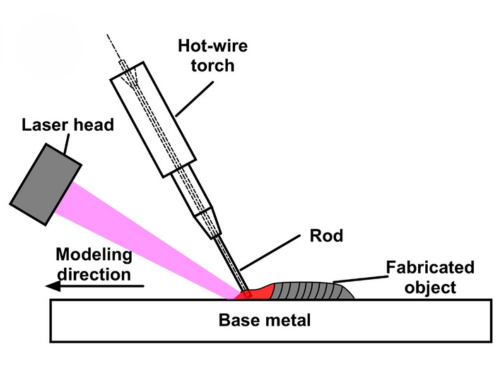

The study focuses on the use of AM, specifically hot-wire laser irradiation, along with two fabrication methods for their experiment. Firstly, hot-wire laser irradiation (also called laser hot-wire welding) is a technique in which a laser beam and a preheated filler wire are combined to increase the deposition rate (how much of the filler metal is added) and efficiency of the process.

One fabrication method used in this study involves direct irradiation on top of the cemented carbide rod, with the rod leading the direction of fabrication. The other method is led by the laser and is irradiated by the laser between the bottom of the cemented carbide rod and the base material (iron). In both methods, the metals are softened instead of completely melted to form the cemented carbide.

“Cemented carbides are extremely hard materials used for cutting tool edges and similar applications, but they are made from very expensive raw materials such as tungsten and cobalt, making reduction of material usage highly desirable. By using additive manufacturing, cemented carbide can be deposited only where it is needed, thereby reducing material consumption,” said corresponding author Keita Marumoto, assistant professor at Hiroshima University’s Graduate School of Advanced Science and Engineering.

Illustration of the laser‑leading method.

(Courtesy of Keita Marumoto/Hiroshima University)

Defect-free, industrial-grade carbides achieved

The results demonstrated this method to be effective in maintaining the hardness and mechanical integrity of conventionally manufactured WC-Co cemented carbides, achieving a base material with hardness of over 1400 HV (a unit representing resistance to penetration), without introducing any defects or decomposition. Materials at this hardness level rank among the toughest used in industry, just below superhard substances such as sapphire and diamond. Producing the cemented carbide molds without defects does appear possible, which is the main goal of this study, though some results vary.

For example, the rod-leading method appears to lead to the decomposition of WC on the upper part of the build, leading to defects in the final product. The laser leading method also had issues maintaining the hardness necessary for success. A nickel alloy-based middle layer was added, and that, along with maintenance and monitoring of temperatures (above the melting point for cobalt, below the temperature of grain growth) lead to a cemented carbide produced via AM without sacrificing material hardness.

The promising results are a springboard for improving upon their work. Researchers would like to see their work here progress to manage the issue of cracking, as well as form more complex shapes.

“The approach of forming metal materials by softening them rather than fully melting them

is novel, and it has the potential to be applied not only to cemented carbides, which were

the focus of this study, but also to other materials,” said Marumoto.

Eventually, fabricating cutting tools, exploring the use of other materials, and further investigating how to improve durability are of top concern for the future of this research.

Keita Marumoto and Motomichi Yamamoto of the Graduate School of Advanced Science and Engineering at Hiroshima University and Takashi Abe, Keigo Nagamori, Hiroshi Ichikawa and Akio Nishiyama of the Mitsubishi Materials Hardmetal Corporation contributed to this research.

About the study

Journal: International Journal of Refractory Metals and Hard Materials

Title: Effect of the hot-wire laser irradiation method and a Ni-based alloy middle layer on mechanical properties and microstructure in additive manufacturing of WC–Co cemented carbide

Authors: Keita Marumoto, Takashi Abe, Keigo Nagamori, Hiroshi Ichikawa, Akio Nishiyama & Motomichi Yamamoto

DOI: 10.1016/j.ijrmhm.2025.107624

Home

Home