Cell sheet preparation for use in tissue engineering and regenerative therapies could be significantly improved with the use of thermo-responsive polymer brushes, adjusted in length and density according to specific cell types

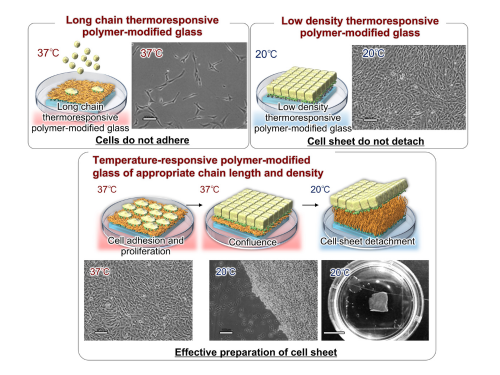

Cell adhesion and detachment behavior of various thermoresponsive polymer-modified glass substrates (Courtesy of Kenichi Nagase/Hiroshima University)

Cell sheets are a single layer of cellular tissue with an extracellular matrix (ECM) surface that allows for easy transplantation into a host, thanks to the glue-like effect of the ECM. Cell sheets, which can be stacked to form dense tissues, are important for use in regenerative medicine and tissue engineering. Transplantation has been used as a successful method of cell transplantation therapy, but some aspects of the technology have not been fully investigated to maximize the efficiency of the cell sheet production. Researchers aimed to understand what the best configuration of structures in thermoresponsive polymers (or thermo-responsive materials that change their properties based on the temperature) would be to get the most out of cell sheet production for advanced tissue engineering.

Researchers published their results in Biomaterials Science in February 2025.

The study focuses on the thermoresponsive polymer poly(N-isopropylacrylamide) (PNIPAAm). PNIPAAm changes its hydrophobicity, or its tendency to repel water, based on the external temperature, leading to its effectiveness in drug delivery systems, biosensors and bioanalysis and diagnostic devices, along with other uses.

Also Read: Aligned stem cell sheets could improve regenerative therapies

“These results indicate that the optimal PNIPAAm brush conditions for cell sheet preparation vary depending on cell type. Thus, modulation of PNIPAAm brush density and length is an effective approach for preparing target cell sheets,” says study lead researcher and author Kenichi Nagase, professor at Hiroshima University's Graduate School of Biomedical and Health Sciences.

When PNIPAAm becomes dehydrated, cell adhesion to the PNIPAAm-modified dish occurs, with cell proliferation occurring around four to five days after incubation. Then, the temperature is reduced to hydrate the PNIPAAm and the cell sheet detaches from the polymer dish. The adhesive ability of the cell is affected by the ECM, but other factors come into play regarding how well cells adhere and detach from the PNIPAAm modified dish. These other factors include the PNIPAAm brush density, which can influence the protein adsorption and brush length, which seemed to influence hydration.

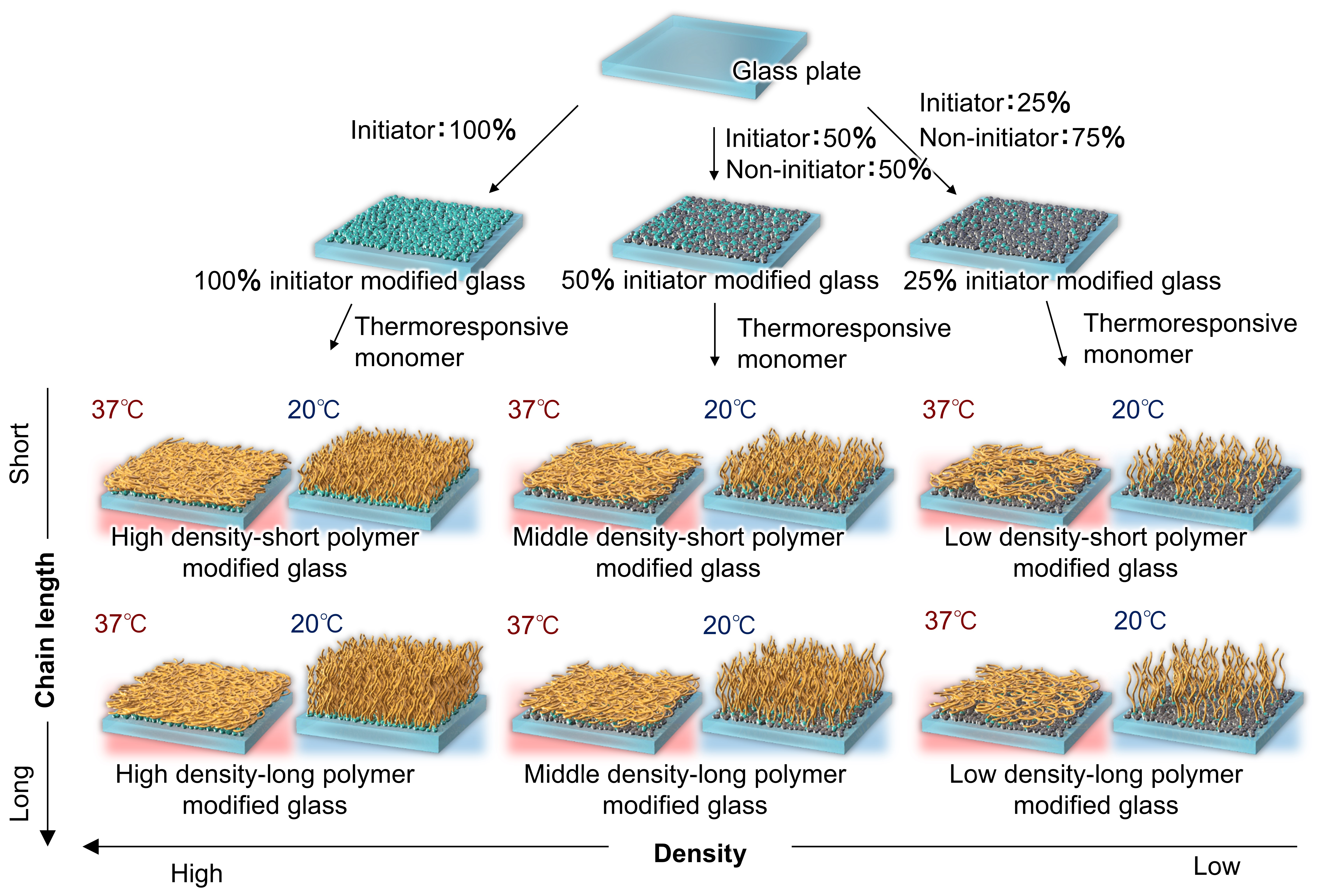

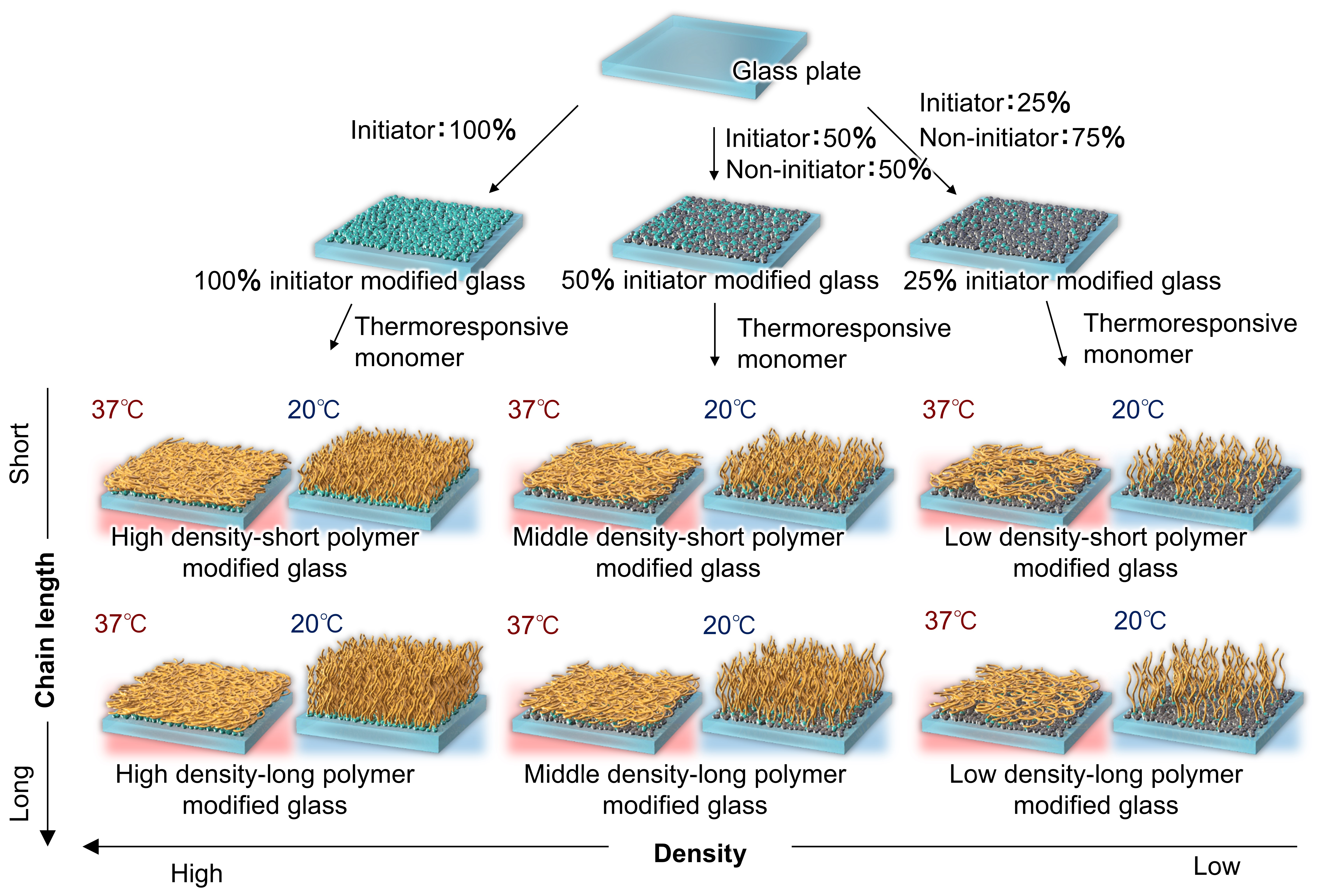

Preparation of thermoresponsive polymer-modified glass substrates with different density and chain length (Courtesy of Kenichi Nagase/Hiroshima University)

The density of PNIPAAm brushes was adjusted by changing the composition of the initiator when the brushes were prepared, and the length was altered by adjusting the concentration of the monomer during preparation. The density and length of the brushes need to be altered according to the cell type for the most efficacy in cell sheet preparation.

A hydrating effect increased along with increasing brush length and fibronectin, a protein found in the ECM, increased adsorption when the brush density of the PNIPAAm decreased. The study focused on investigating six different PNIPAAm brush types, confirming that different cell types will require different brush lengths and densities for the best results.

In the future, researchers would like to put the thermoresponsive culture dishes out into the commercial market for clinical use. This will further advance the already rapidly growing field of tissue engineering and regenerative medicine. The ultimate goal is a more tailored approach to cell sheet production by adjusting the polymer brush characteristics to best suit the type of cell targeted.

Nagase, along with Teruo Okano from the Institute of Advanced Biomedical Engineering and Science at Tokyo Women’s Medical University and the Cell Sheet Tissue Engineering Center at the University of Utah, and Akihiko Kikuchi and Minami Watanabe of the Department of Materials Science and Technology at Tokyo University of Science, contributed to this research.

Grants-in-Aid for Scientific Research from the Japan Society for the Promotion of Science, the Precise Measurement Technology Promotion Foundation and the CASIO Science Promotion Foundation made this research possible.

About the study

- Journal: Biomaterials Science

- Title: Effective cell sheet preparation using thermoresponsive polymer brushes with various graft densities and chain lengths

- Authors: Kenichi Nagase, Minami Watanabe, Akihiko Kikuchi & Teruo Okano

- DOI: 10.1039/D4BM01705F

Media Contact

Inquiries on the study

Kenichi Nagase

Professor, Graduate School of Biomedical and Health Sciences

E-mail: nagase * hiroshima-u.ac.jp

(Note: Please replace * with @)

Inquiries on the story

Hiroshima University Public Relations Office

E-mail: koho * office.hiroshima-u.ac.jp

(Note: Please replace * with @)

Home

Home