Prototype of the world’s first foldable mobile bridge complete!: Will Kakehashi-kun act as a bridge for the world?

In this edition of Research Now, we interviewed Assistant Professor Ichiro Ario, Division of Civil and Structural Engineering, Department of Social and Environmental Engineering, Graduate School of Engineering.

(2009 December 15th, Interviewed by Public Relations Group, Community Collaboration and Information Policy Office)

Profile

One winter, when Assistant Professor Ichiro Ario was a third year student at junior high school, he decided that he wanted to pursue a career in which he could contribute to society, and decided not to go to comprehensive high school but to Akashi National College of Technology instead. He said he was greatly influenced by his elder friend at school whom he respected. But then there was an event that changed the career he had envisaged.

He participated in shore protection work as an intern at the Kobe No. 3 Harbour Office of the former Ministry of Transport, where he began to calculate the strength of a concrete block that would not break if a ship crashed against the pier, and would not be destroyed by an earthquake. He was wondering how to overcome these problems when he came across a certain book.

The author of the book was a teacher at his college. He knocked on the door of the teacher’s laboratory without any hesitation, and told of his original intention to work in a way that would benefit society. However, he transferred to Nagaoka University of Technology Undergraduate and Graduate Schools, where he completed his doctoral courses. He came to Hiroshima University to take his post at the Cluster IV (currently the Social and Environmental Engineering, link to a Japanese page), Faculty of Engineering in 1997 after working for a private company and working as a teacher at Wakayama National College of Technology. Fate led him to take the path of a researcher.

Cylinder’s symmetry breaking?

Dr. Ario’s major research field is applied dynamics and structures analysis. He says that structures built using various materials, such as bridges and buildings, are strong but they have the demerit that they can suddenly collapse if they begin to develop a wrinkle. “For example, a cylindrical can, even an aluminium can, is very solid when subjected to a vertical force. I think many people have noticed how hard it is to crush an empty can in that direction. But if we twist it a little, pressing at one point, we can crush it with ease. Plastic bottles are also unexpectedly sturdy. The wrinkle that may develop for many different reasons, such as the structure’s own rigidity or compressing power, can suddenly produce an interesting shape. Do you know why?” he asked me. As soon as it was apparent that I did not know the answer, he rolled up two empty coffee cans back to back in some A4 size paper, and compressed it with a little bit of power. He said “Please remember what you see because I will explain what happens later”. Wrinkles were left in the paper along the regular folds.

Firtst, twist two empty cans that have been placed back to back.

Second, twist them with a little bit of force.

Regular folds can be seen on the paper.

Developing the first mobile bridge in the world!

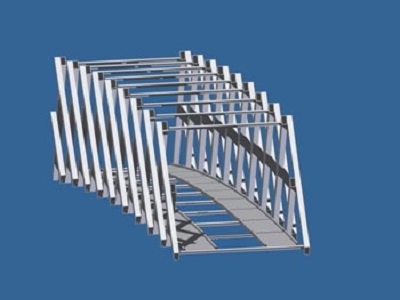

In September 2009, Dr. Ario gave a presentation at the Japan Civil Engineering Society in which he told how he had developed an original prototype of a foldable bridge (a mobile bridge). This bridge enables infrastructure to be quickly restored and allows victims to be rescued in the event of a disaster.

*Press release of Hiroshima University, 24 August 2009 (Japanese Page)

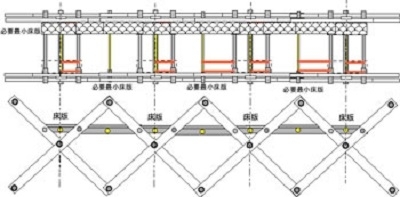

This bridge was completed as a joint development in the field of fundamental construction technology with the Japan Construction Method and Machinery Research Institute. It is 0.5 meters wide and can compress and stretch like an accordion from 0.5 meters to 9 meters in length (it starts off being 6 meters long). It is the very first foldable and movable prototype of a compact size that people can also walk on.

*Japan Construction Method and Machinery Research Institute Website (Japanese Page)

A weakness of prefabricated bridges currently in use

Every Regional Development Bureau of the Ministry of Land, Infrastructure, Transportation and Tourism prepares and stocks equipment necessary as disaster measures such as drainage pump cars, lighting cars, and emergency (prefabricated) bridges. They are utilised in the event of a disaster.

Current temporary bridge (it takes 4 to 7 days to assemble)

Dr. Ario pointed out, “But because an emergency bridge is generally based on a design that needs to withstand the load of a large vehicle (a 20-ton trailer), it is a very heavy structure even if it is a short bridge, and it is not designed to allow victims of a disaster to be helped or rescued. It takes about 20 trucks to carry the emergency bridge, and also needs a wide space for assembly. It takes a lot of time to assemble the emergency bridge in a disaster-stricken spot despite time being of the highest priority in such emergencies. This is a big demerit in risk management in our contemporary society”.

A hint for development

He thought, “I should design an incomplete bridge that can be folded into many layers in advance, and then expanded when necessary”. One day five years ago, he saw his eldest son playing with a toy pistol made of resin. The barrel was attached to a scissor-like section and extended when the trigger was pulled. This gave him an idea: “We could use that kind of design for the bridge if we doubled the stretching part, and made use of its stretching function. It should be stronger!”

The folding structure is like that of an accordion door gate. Although the door of the gate can expand and contract, because of its lack of strength and tendency to become easily unstable against forces in a non-planar direction where the deformation clashes with the direction of the force, creating a right angle to the stretching direction, it would be impossible for a vehicle or a person to use it. Though a foldable bridge for military use has been developed, it has quite a different structural form and is very solid so that tanks can go over it, and can only be folded into two at best. Of course it must also be extremely expensive.

The materials need to be light and strong to make the bridge mobile, and the bridge needs to have a dynamical balance, structural stability, and optimal structural form. In reality, designing such a bridge was not so simple, as complex optimisation problems arose. Dr. Ario thought that it would be possible to fold the bridge if its structural instability could be controlled. Because present-day computers are left with the burden of completing complex calculations, increasing the risk of a mistake, Dr. Ario designed a failsafe system to control any structural instability. Having planned this far, he now thought, “Is this not enough to build a foldable bridge?”

Learn the foldable structure

Currently, it is theoretically known that there is latent multiple structural instability in multiple folding. But no one has thought about folding a big structure like a bridge several times because it would be impractical and very risky. They might rethink the possibility of folding a bridge if it was possible to control the structural instability when we think about it from a different angle. But first it is necessary for us to understand foldable structures to solve this problem.

If a bridge were foldable, how would it be folded? What is necessary to fold it while maintaining its strength? What is the most efficient way to fold it?

The folding paper on which the regulated folding pattern appears, based on the above-mentioned “Cylinder’s symmetric breaking,” is a hint. Folding is a traditional Japanese art, exemplified by origami, the art of folding paper. However, the dynamics involved in folding were an unknown area for Dr. Ario. At the time, he got to know a Fracture Mechanics researcher who academically researches the folding patterns of origami, calling it “Origami (Folding) Engineering” and this encouraged Dr. Ario to find a physical solution to the dynamical problem of how to fold three-dimensional cylinders on a plane surface using the smallest dynamical energy.

An example of the folding cylindrical structure principle using an origami technique and symmetry-breaking phenomena (at the Non-Linear Research Centre, Bath University in the UK in Dr. Ario’s overseas study, 2003)

He came up with an idea to make multiple-structural stability possible as a whole bridge by combining the small controlling force, leverage, and smart structure concept(*1). Developing a prototype became a real possibility. And developing a foldable bridge using the origami approach, which had thus far been thought to be impossible, began to seem feasible with this prototype development.

(*1) A completely new structural concept in which a sensor attached to (implanted in) a structure acts in a seemingly intelligent way, finding out the impact and defect that the structure is subject to from the outside, healing it, and causing it to vibrate or change to the optimum shape.

Much force acts on the base used to prop up the bridge.

A design drawing of the prototype

Concept of a completed mobile bridge

Folding plastic bottles and empty cans can help reduce the volume of waste. Currently, Dr. Ario is developing a way to reduce the volume of drink containers, participating in collaborative research with Nihon Yamamura Glass Co., Ltd., and has been designing various interesting shapes that these containers can be formed into.

Nihon Yamamura Glass design (right) and Trial product (left)

Preparation for natural disasters

“Japan has greatly suffered from natural disasters such as earthquakes, tsunamis, and typhoons (heavy rains). We must continue to live with these disasters in the future. To do this, we will need to analyse past disaster situations and establish a responsive system for preventing disasters so that we can quickly save many human lives using our knowledge of science and technology”, Dr. Ario insisted. “It is our government’s important task to protect us against disasters that carry large-scale risks. As the proverb says, ‘if you are prepared, you do not have to worry’; we need to build our nation (establish a disaster-prevention foundation) to thoroughly protect human lives and peoples’ fortune against disasters”.

“We have learned lessons on how to prepare for disasters through lots of historical events such as Itamura no hi, the story of a village that saved its members from a tsunami disaster by setting fire to harvested rice. But we have lost many irreplaceable lives and fortunes by repeated disasters like torrential downpours. I believe we must give ordinary citizens’ needs top priority when we are pressed for time fighting a disaster. Some victims have said things like ‘We were given an evacuation order but we could not escape because of the ferocity of the downpour,’ and we should seriously consider these sad words”, says Dr. Ario. He always rushes to the locations of earthquakes and downpours to conduct surveys when they occur. His words based on reality are persuasive and impressed me (the interviewer).

Click here to read ‘A survey report of the bridge carried away by downpour on 9 August 2009. (Japanese Page)

A bridge carried away by a downpour at Sayo, Hyogo Prefecture on 9 August 2009

A truss bridge carried away by a downpour on 9 August 2009

A village that was isolated when a nearby bridge broke

Another picture of the bridge destroyed by a downpour on 9 August 2009

High Expectations for Kakehashi-kun!

The technology developed this time is very groundbreaking. It reduces the time needed for construction because a bridge can be given an expansion mechanism in advance. Though there are some challenging issues to be overcome, by establishing this technology it could become possible to carry a bridge to a disaster zone by folding it into a compact size, and then expanding and constructing it at the location. Different kinds of conditions and technical issues depending on the disaster’s scale and situation at the stricken spot will need to be accounted for when putting the bridge to practical use. However, we can expect a foldable bridge to be useful for quickly rescuing people and securing a lifeline.

It looks compact, doesn't it?

Afterword

*Some links given below will direct you to a Japanese page.

Students planned “The Mobile Bridge Exhibition and Cross the Bridge Experience” that was open to the public and drew attention at the university festival held in November 2009. One early morning in December, Dr. Ario had a TV interview and his study titled “HU developed the first mobile bridge over the world” was broadcasted throughout Japan. Kakehashi-kun No. 3 was produced thanks to great support from the School Workshop’s professional craftspeople assigned from Hiroshima University’s Technical Centre, which has advanced technology in each field. Dr. Ario speaks of wanting to continue to make improvements with them while conducting practical experiments. Associate Professor Yuuji Sakuno from the Department of Social and Environmental Engineering in the Division of Global Environment Engineering [the Cluster IV, Faculty of Engineering (Social and Environmental Engineering) ] used a balloon to take photographs and create a calamity map that could be used to give aid to victims. Despite saying the budget does not permit them to continue their research, he says he has high hopes for Kakehashi-kun! Professor Ario’s face lights up at the possibility of making a social contribution domestically and internationally using Kakehashi-kun No. ○. Now we just have to find sponsors, right professor? (O)

Technical staff that manufactured the prototype and the colleagues and students who assisted with the experiments

Home

Home